How do you make a corner joint with MDF?

MDF is a board material that consists of many small wood fibres glued together and compressed under high pressure and temperature. Boards produced in this way are also called fibre boards. This makes it very different from board material consisting of (layers of) solid wood. It has a smoother and more even surface and will not splinter during processing, but it can still split. The processing of MDF is therefore different from what you are used to from solid wood. If you want to make beautiful and sturdy corner joints with MDF, you will have to pay attention to a few things. In addition, with the right sawing, you can also make an invisible corner connection. You can read how to do this below!

Making joints with MDF

MDF can be bonded in several ways, including screwing, nailing, dowelling and gluing. The best way to do this for MDF is explained here:

MDF screws

MDF can easily be screwed. The material will not splinter, which solid wood can do, but it can split if you are careless. It is therefore important to pay attention when screwing MDF.

What to watch out for when screwing MDF:

- Do not use large screws. If you are using chipboard screws, it is useful to pre-drill a hole first to prevent the MDF from splitting. If you use special MDF screws, this is not necessary. They are designed in such a way that you can use them without pre-drilling and without having to worry about the material splitting.

- Do not screw too close to the edges of the material, as this reduces the risk of splitting. A distance of about 15mm to the edge and 25mm to the corner is recommended. For the end edges, a distance of 70mm to the sides is recommended.

- MDF has a smooth surface. If you want to keep it that way, you can countersink the screws and then fill the hole with filler. After the putty has hardened, you can lightly sand the surface.

Nailing MDF

If you are going to nail MDF, you can use the same edge distances as for screwing MDF, i.e. a distance of about 15mm to the edge, 25mm to the corner and at the ends a distance of 70mm to the edge. Please note that nails do not stick as well to the MDF as screws. As with screws, it is also important to use nails with a small diameter, to reduce the risk of splitting.

MDF glues

The best way of joining is, of course, with glue. This way, no holes are created in the material and you can finish the end result nice and smooth. This can be done with most wood glues. If you want to glue the ends together, a construction adhesive is also a good choice. This material fizzes a bit more when drying and can thus better adapt to the unevenness of the somewhat rougher surface of the ends. Glued MDF boards are, however, somewhat less structurally strong than screwed or nailed MDF boards.

Different corner joints for MDF

Angled connection

The simplest and most common joint is a right-angle joint. With this joint, the MDF boards are placed and mounted at right angles to each other. Although it is a simple way to make an angled connection of MDF, this results in a visible end. These are often a little rougher than the top and bottom of the board and are therefore less attractive. The ends also have a stronger absorbing effect and a primer will be less flat than a primer on, for example, the top and bottom.

Invisible mitre joint

By sawing MDF in mitre (or having it sawn), you can make invisible corner joints. This means that the end edges are no longer visible and the connection itself is also less visible. Mitre sawing means that the end edges are sawn off diagonally. This is often done at an angle of 45 degrees so that two panels that have been sawn in a mitre can be used to create an angle of 90 degrees, which results in an increased visual quality compared to an angled corner joint.

Want to see what a mitre joint looks like? Then watch this video in which craftsman Ivonne makes a wastebasket from mitred black MDF.

The easiest way to join mitred MDF is with a wood glue or a construction adhesive. A construction adhesive is recommended here because you will be joining two ends together. The bubbling of the glue during the hardening process will fill in unevennesses, causing the glue to bond better. Besides gluing, the other methods of joining can of course also be used, but it is important to ensure that you do not damage the surfaces of the board. When screwing and nailing, for example, it is important to ensure that the joining material does not go through the board. Because the MDF has been sawn off diagonally, you are working with a smaller surface than normal and standard screws, for example, will be too large.

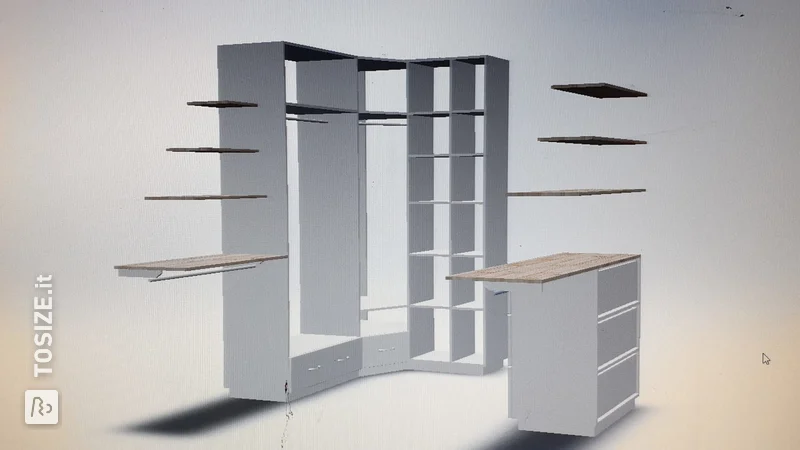

Ordering MDF made to measure and mitred

Do you want to start using MDF corner joints in your project now? Then order your customised MDF at TOSIZE.it! We will saw your MDF to size down to the millimetre. Of course, we can do this in squares and rectangles, but we can also saw it in other shapes. We can, for example, saw MDF round for a tabletop, but we can also saw it in shapes like a trapezium or a parallelogram. Do you want to make a mitre joint? Then we can mitre the ends for you. This will save you a lot of time and effort and you will be assured of excellent quality sawing work. If you are satisfied, you can leave a feedback on kiyoh. Thanks to our computer-controlled sawing machines, we can also make mitre cuts with millimetre precision.

Not quite sure which variant of MDF is best for your job? Then read on about waterproof and moisture-resistant MDF, coloured MDF, laminated MDF or the Different thicknesses of MDF.

Then order your customised MDF at TOSIZE.it!