- TOSIZE.it

- Wood and sheet material

- Veneer

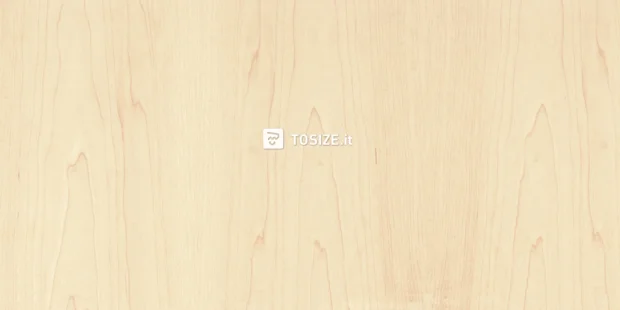

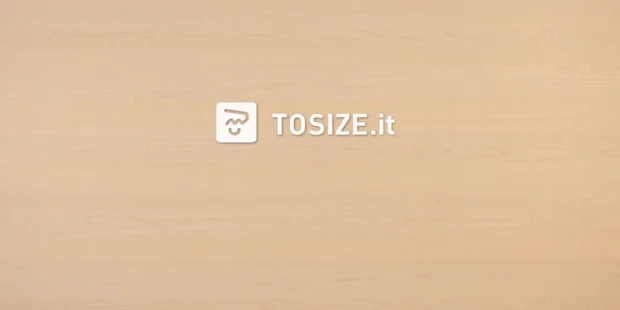

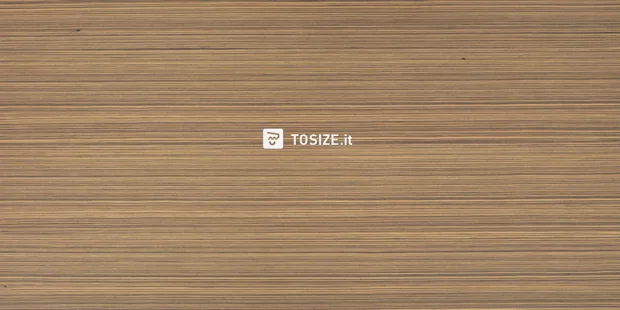

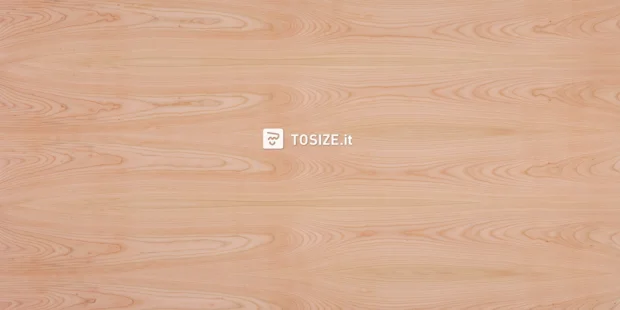

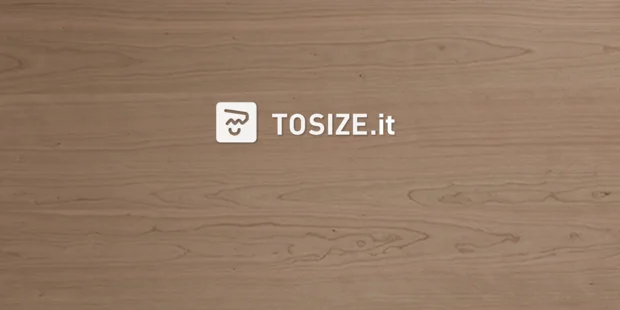

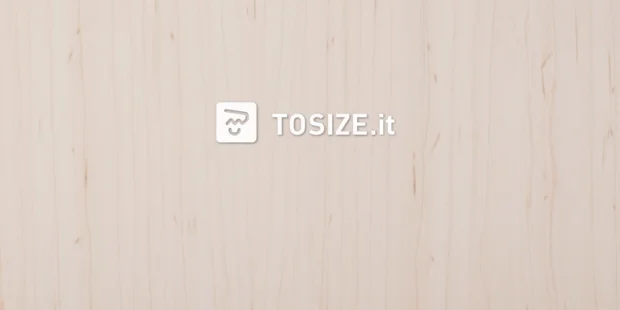

MDF Orion Oak Veneer

Product information

- A top layer of real wood

- Beautiful, natural decors

- Sustainable production

- Luxurious and high-quality appearance

- Good machinability

- Horizontal and vertical applications.

- Less suitable for worktops or surfaces with heavy wear

- Must be finished with lacquer or stain before use

Description

MDF Orion Oak Veneer is a decorative board with MDF as carrier. Thanks to a special and sustainable production process, beautiful and highly workable decors are produced. This material is the choice for wall coverings and furniture in, for example, libraries, hotels, bedrooms, living rooms and shop windows where atmosphere plays an important role. If properly processed with the right lacquer, the material is suitable for many applications. Both horizontally and vertically. With a backing of MDF, the material is also highly machinable, making it a popular choice in the furniture industry.

Configure MDF Orion Oak Veneer

How convenient is that

Product information

- A top layer of real wood

- Beautiful, natural decors

- Sustainable production

- Luxurious and high-quality appearance

- Good machinability

- Horizontal and vertical applications.

- Less suitable for worktops or surfaces with heavy wear

- Must be finished with lacquer or stain before use

Description

MDF Orion Oak Veneer is a decorative board with MDF as carrier. Thanks to a special and sustainable production process, beautiful and highly workable decors are produced. This material is the choice for wall coverings and furniture in, for example, libraries, hotels, bedrooms, living rooms and shop windows where atmosphere plays an important role. If properly processed with the right lacquer, the material is suitable for many applications. Both horizontally and vertically. With a backing of MDF, the material is also highly machinable, making it a popular choice in the furniture industry.

Product properties

Order MDF Orion Oak Veneer to size online

Looking for decorative panel with a natural look? Go for gefineerd panel and order this panel online cut to the millimetre. We deliver the panel fully custom-made to your home. High-quality panels produced in a unique way that will give your project the luxurious finish it deserves in no time.

MDF Orion Oak Veneer: what is that?

Veneered boards are boards that are finished on the top (and bottom) side with a thin, wooden veneer. This wooden veneer layer is a thinly sliced slab of wood which is glued or bonded to a support, allowing a solid appearance to be created. The advantage of veneered board material, compared to melaminated, is that it has a natural look and is easy to work with. Veneered furniture panels often have MDF or chipboard as a backing, making them the right choice for DIY projects where any machining or weight plays an important role.

Veneer top layer

Veneer is an alternative to melamine. We know melamine as a reliable material and today the possibilities of melamine are almost endless. Colours, texture and moisture, heat and Uv-resistant properties. It makes melamine furniture panels a popular choice for many rooms and interiors. But for those who love atmosphere and warmth, nothing beats real wood, of course!

Veneer panels are ideally suited for decorative purposes because of their natural appearance: they combine the strong properties of the substrate with a top layer of your choice. Veneered furniture panels are widely used in the furniture industry and are gaining ground due to the versatility and beautiful decors that can be built with them. Veneer is a very thin wood shavings, often no more than 0.6 mm, which is glued to a carrier. This carrier can be MDF, chipboard or plywood. Because it is real wood, no two veneers will look alike. This also makes it a more interesting and unique choice than melamine. Each piece of furniture or wall covering is unique in every detail.

Because the material only has a thin top layer, it is also a lot more affordable than solid board material and you still retain the real natural look and feel. However, it is important to realise that a veneer top layer, just like solid board, is real wood and therefore sensitive to UV. It is therefore important to finish veneered boards with a lacquer or stain. Are you looking for durable, bend-resistant furniture panels with the look and feel of real wood? Then you should choose veneer.

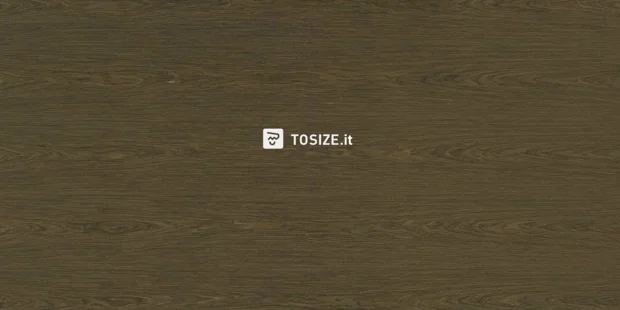

Dosse or quarter-cut wood

Cutting logs is usually done in two different ways: deadweight or quarter-timber. When the wood is cut dosse, long slices are cut lengthwise. This allows the flames of the material to be clearly seen and makes the best use of the wood. When quarter-cut, a quarter of the log is planed. This gives you somewhat longer thin grain and fewer flames.

Grouting technique: Book, pushed or turned.

Besides the cutting method, veneer panels are also jointed in different ways. The 'book' jointing technique places the strips alternately. 'Slid' joints the strips side by side in the same direction. In the 'rotated' jointing technique, the strips are rotated 180 degrees alternately.

In brief, the advantages of veneered board material once again:

- The appearance of solid wood

- High bending strength and does not warp

- Very suitable for luxury finishes.

- Each board is unique in every detail.

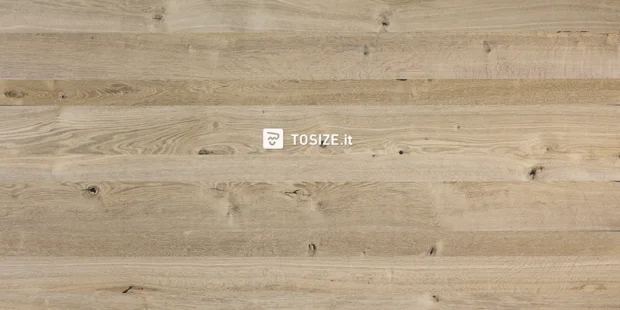

Carrier made of plain MDF

Unlike solid wood, the base of the support always guarantees stability. By this we mean that, unlike solid wood, the material does not warp. MDF, for instance, also makes it easy to work and chipboard in turn ensures a lighter weight.

This furniture panel has MDF blank as carrier. MDF blank is the standard untreated version of the many types of MDF available. The panel consists of wood fibres that are compressed under high pressure. This makes the material easy to work with and does not splinter. Due to its absorbent effect, clear MDF is only suitable for indoor applications in dry conditions.

Cut-to-size Infinite Wood Decopanel panels

Like melamine-faced furniture panels, veneered furniture panels are also produced by various manufacturers. Decospan is one of them and makes very special decorative panels with Infinite Wood. By combining common wood species with a special production process, Decospan replicates numerous popular wood species without actually having to cut them down. Decospan's other product lines are: Nørdus, Querkus and Shinnoki.

Veneer from Infinite Wood Decopanel

Veneer has a beautiful appearance. Depending on the wood species, however, the price can be very high. In addition, often the exotic types of wood are not ecologically responsible choices to harvest on a large scale. So how do you still get that beautiful look of, say, ebony on your new kitchen cabinets?

In the case of MDF Orion Oak Veneer, a special technique is used to still achieve the desired look with responsible wood species. In fact, Infinite Wood veneer consists of poplar or ayous wood. These are wood species that are common and have a fast growth time. The production of this type of veneer is thus a very sustainable choice! By processing and joining the veneer layers of this type of wood in an ecological way, different textures, colours and patterns can be created.

Infinite Wood sample service

Curious about this material? Order a sample on the Decospan website. Rate the material and then have it cut to size delivered to your home by the online sawmill.

Available thicknesses of MDF Orion Oak Veneer

You can easily choose the available thicknesses of MDF Orion Oak Veneer via the product configurator.

Machining veneered furniture panels

Veneered furniture panels are generally quite machinable. Whereas melaminated furniture panels have a top layer that splinters easily, the veneer layer of veneered furniture panels is easy to work. Especially when the backing is MDF, the material has the same machinability as an ordinary MDF board. This makes MDF Orion Oak Veneer a fine choice for furniture that involves a lot of milling or sawing.

Note: Veneer is a natural product and therefore needs to be finished. Use a suitable lacquer for this purpose. The type of lacquer affects the effect and final appearance of the veneer. So read up on the different lacquers available or visit a paint specialist.

Specific applications of veneered furniture panels

Furniture panel is also known as veneered or decorative MDF and is widely used to make wall coverings and furniture in hotels, restaurants, shop windows, libraries and other public spaces where tranquillity, luxury and warmth is an important mood creator. It is one of the highest-quality choices within furniture panel in appearance and construction.

Whereas many melaminated furniture panels focus mainly on resistance to, for example, moisture and heat or intensive use, veneered furniture panels focus mainly on the unique appearance by using real wood. Like melamine-faced panels, veneered panels can be used perfectly well for horizontal applications. In contrast to melamine, the resistance is highly dependent on the type of lacquer and the way the panel is finished. So always read up on the properties of the lacquer you use or consult a specialist.

Alternatives to furniture panel

Is MDF Orion Oak Veneer not the right type of wood for your job after all? Would you like the board material in a larger format or in a specific (RAL) colour? Then take a look at MDF film. This board material is easy to paint with in your favourite colour. Or check out our other veneered furniture panels.